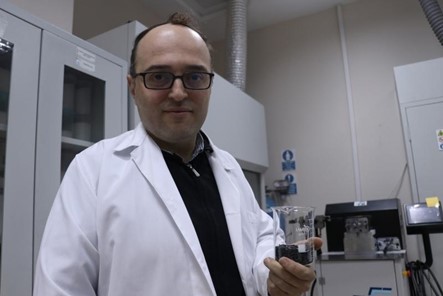

Our third External Expert on board is Assistant Professor at Yalova University. Yalova University is located in the small city of Yalova in the south Marmara region. One of the specific educational fields that this university offers is polymer materials engineering. Polymer Materials Engineering is interdisciplinary engineering that is made up of basic engineering fields of chemistry, materials, and mechanical engineering. In the Department of Polymer Materials Engineering, where detailed education is provided on the synthesis and physical/chemical properties of polymers, processing of polymer materials, and rheological, thermal, and mechanical properties of polymers, not only undergraduate education but also a master of science and doctoral degrees are offered. Moreover, within the scope of university and industry cooperation, many projects are developed on a variety of issues such as the development of composite structures with high added value, environmentally friendly materials, and innovative polymeric materials.

Dr Alper Kaşgöz completed his undergraduate education in the Department of Chemical Engineering at Istanbul University in 2010. Thereafter, he did his master’s degree in the analysis of the rheological properties of carbon-reinforced cyclic olefin copolymer composites and his doctoral degree in the development of polymer composites with electromagnetic shielding capacity in the same university. He has been working at Yalova University since 2017. His main fields of research are the development of thermostatic-based polymer blends or composites for specific purposes, analysis and optimization of rheological, thermal, and mechanical properties of polymeric materials, and processing of polymers through extrusion and injection systems. He is currently teaching undergraduate and graduate courses on the processing and rheological properties of polymer materials in the Polymer Materials Department of Yalova University.

Hello Dr. Kaşgöz, thanks for your time and nice meeting with you. As an expert in the field of polymer process and rheology, what do you think are the main interesting points of REVOLUTION polymer processing?

“I should say that the REVOLUTION project is the most exciting project among the projects I have been involved in so far. We are witnessing use of recycled plastic products in various fields. However, when we consider the issue from the perspective of performance, we can see that the fields that do not require much strength in terms of mechanics in these areas of use are more prominent. Besides, we see that there are fluctuations in the quality of products depending on the quality of the recycled raw material in these fields. The project in question involves handling of many strategic components in an automobile from various perspectives. I specifically use the term handling, because it consists of the development of a complete system that includes not only production through a plastic injection system by taking the recycled product from a certain source, but also standardization of the raw materials taken from the source and controlling the process online by way of artificial intelligence systems, and self-optimizing the production at the same high quality. The components determined are just an indicator which show that the system works successfully.

When considered in this sense, the most exciting feature of the project is that through artificial intelligence, the classical polymer process methods such as extrusion and injection can be made self-monitoring and self-optimizing, and a system can be developed in which with the data obtained at the moment of production through the derivation of various rheological parameters and based on the production parameters that will eliminate the need for a quality control laboratory, quality control can be tracked real-time.”

From your point of view, which will be the project acceptance to the market?

“The project has been designed in such a way to focus on the problems of the present time and the future and to aim a multi-perspective solution in collaboration with the stakeholders in the industry. The slogan “Future is Now” supports this design of the project. Therefore, I believe that the outputs of the project will be adopted more in time, and that these outputs will be the starting point for many different applications in the future. However, I also think that in the initial phase, the algorithm that involves a high rate of recycling and is created in order to obtain high quality products will be particularly welcomed by the industry.”

Regarding the policy framework, which is the degree of adjustment of REVOLUTION with the current and planned laws? What Will REVOLUTION need to do to ensure solutions comply with current and planned recycling laws?

“I should again emphasize the design of the project that aims to serve not only the problems and needs of today but also the requirements of the future. When the objectives of the project are considered, it is seen that target criteria that are beyond today have been determined. For example, the use of recycled products is targeted up to 80%. Therefore, I believe that the project outputs will not pose any problems in terms of current laws. I also think that the project data can be taken as reference in determining the criteria that will enforce the producers in a technical sense in the laws to be made in the future.”

How can REVOLUTION leverage industrial processes (to create opportunities and grow)?

“A significant improvement will be ensured in the industry with the increase in the variety of the components produced from recycled products within the scope of the REVOLUTION project. However, more importantly than this, I believe that with the efforts to produce lighter components within the scope of the project, important contributions will be made to both commercial and environmental issues that the automotive industry has focused on in recent years such as increasing the range of electric automobiles, decreasing energy consumption, and reducing CO2 emission.”